In FY 2022 MC has visited domestic meat processing company, a poultry supplier of MC’s subsidiary Foodlink Corporation. This year, an inspector from DNV Business Assurance Japan Co., Ltd., a third-party inspecting company, has accompanied with MC and evaluated the supplier’s sustainability management system by interviewing the supplier’s management and employees.

The evaluation was conducted based on Mitsubishi Corporation Supply Chain Checklist, confirming the supplier’s validity of sustainability management system and its implementation. The checklist items related to personnel and labour affairs were generally properly managed. However, since some policies and procedures have not been documented, MC requested that these policies and procedures be documented. Regarding safety and health and environment issues, only a small part of policies and procedure is documented and management seemed to be dependent on individual employees. Although a certain amount of education and training is provided to the employees and no accidents have occurred yet, MC recommended that policies and procedures be established and thoroughly communicated in the future.

Please refer to the attached report for more details.

In FY2021, MC conducted an online meeting and interview*This meeting and interview were conducted online due to COVID-19 restrictions.* with the management team and employees of Fisheries Cooperative Association of Mitsushima-cho, a supplier of tuna (located in Nagasaki Prefecture, Tsushima City) to one of MC’s subsidiary companies, Toyo Reizo.

In the meeting, in addition to the external environment related to sustainability, MC also explained its sustainability initiatives (our basic stance on human rights and our efforts to identify and address sustainable supply chains as one of our key management issues). The meeting provided an opportunity to deepen their understanding of sustainability and the importance of MC's initiatives.

In the online interview, MC learned that the company is engaged in activities that lead to sustainable fishing such as collecting debris from the ocean, that there have been no human rights violations or other problems due to its efforts to create an open work environment, and that employees engaged in work that involves occupational health and safety concerns are not only provided with appropriate training, but that their personnel assignments are made such that workloads are not unevenly distributed.

Through the interview, MC confirmed that the company’s internal policies on environmental and social considerations mentioned above were not clearly documented in writing. MC therefore requested that these policies be clarified in order to ensure thorough awareness of the policies and to deepen efforts related to sustainability initiatives.

Working in partnership with suppliers, MC will continue to promote sustainable operations throughout its supply chains.

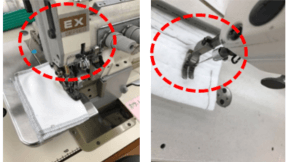

In the fiscal year ended March 2021, MC employees visited a garment factory in Japan, which supplies apparel products to MC’s subsidiary Mitsubishi Corporation Fashion Co., Ltd., and conducted interviews with employees and company management.

As a result, MC confirmed that: (1) employee rights are respected throughout the employment process, including in recruitment, execution of employment contracts, training and management of working hours; (2) methods have been established to create an environment where on-site managers exchange daily reports with each employee, and employees can submit opinions to management directly; (3) on the environmental side, efforts are made to utilize LEDs for fluorescent lighting in the factory, reuse scrap materials, etc.; (4) information regarding industrial health and safety, such as wearing a mask to prevent inhalation of product particles, etc.; indoor ventilation and evacuation routes is properly displayed; (5) and, although the number of accidents at MC is small at one or two incidents per year, efforts are considered together with employees to prevent accidents, such as using stepladders with handrails and installing handrails on stairs to prevent falls, which are the main causes of accidents. MC aims to achieve continuous improvement in its operations.

Minor issues relating to health and safety were pointed out during the visit, but they were addressed promptly after inspection.

Working in partnership with suppliers, MC will continue to promote sustainable operations throughout its supply chains.

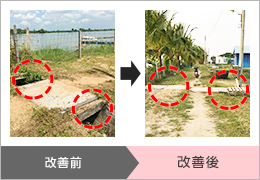

In the year ended March 2019, MC employees visited B. Foods Product International (BFI), a poultry processing plant in Thailand which supplies fresh and processed poultry products to MC subsidiary Foodlink. Interviews were conducted with employees and company management in order to cultivate a better understanding of BFI’s sustainability practices. MC was able to confirm that BFI has a mechanism in place to internally communicate Betagro Group’s sustainability policies and the CEO message which states that BFI must consider environmental and societal impacts when doing business, and also that these points are being implemented into operations.

Through the interviews, MC was also able to confirm that employee rights are respected throughout the employment process including recruitment, execution of employment contracts, training and management of working hours. On the environmental side, MC confirmed that BFI has set targets to reduce greenhouse gas and waste emissions, and that wastewater is treated through an appropriate treatment process.

During visits to BFI’s plants, MC confirmed that adequate measures are put in place to prevent knife-related accidents within the facility. For example, employees appropriately wore uniforms and protective equipment, floors were kept clean to prevent slips and falls, and signs were posted within the facility to communicate accident prevention measures to employees.

Minor issues relating to health and safety were pointed out during the visit. For example, it was identified that some equipment in the facility were situated close to the ground and that there was a possibility of employees injuring their heads, so MC requested safety measures to be implemented accordingly. Promptly after the visit, BFI considered necessary improvement measures and set up a warning sign written in three languages in order for all employees to be able to understand.In the event of an accident, BFI conducts an investigation and agrees on preventive measures together with employees, and this has contributed to reducing the number of accidents. From this example and from the way BFI adequately adopted improvement measures following the site visit, MC was able to confirm that BFI constantly reviews their operations and takes necessary actions for remediation.

Working in partnership with suppliers, MC will continue to promote sustainable operations throughout its supply chains.

In the fiscal year ended March 2018, MC employees visited two suppliers in Vietnam: Viet Tien Garment, a garment factory, and Vinh Hoan Corporation, a company involved in aquaculture and processing of pangasius. Interviews were conducted with employees and management executives in order to cultivate a better understanding of best practice in each industry.

At the Viet Tien Garment factory, through interviews with management, MC was able to confirm that sustainability has been integrated into MC’s core strategy. As part of its strategy to improve efficiency, Viet Tien Garment is in the process of setting energy-saving targets and strengthening its occupational health and safety (H&S) standards. In addition to interviews, MC visited Viet Tien Garment factory and recognized that an H&S manual is distributed to workers and H&S signs are clearly posted around the factory to prevent accidents. Factory floors are kept clean at all times to prevent personal injuries, and working hours are managed by a fingerprint authentication system to prevent overtime.

Vinh Hoan Corporation also takes a serious approach to sustainability as their management policy. MC has acquired several certifications such as ASC*1Aquaculture Stewardship Council: Certification program for sustainable aquaculture.*1 and BAP*2Best Aquaculture Practices: Certification program for safe and sustainable aquaculture.*2 as part of its efforts to differentiate itself from its competitors. During the site visit, MC recognized that hygiene standards were observed properly (including the use of worker uniforms), and also confirmed that its wastewater treatment process is independently verified by a third-party. Although an H&S minor issue was identified during the visit, improvement measures were promptly agreed upon and adopted soon after the visit.

As a result of these visits, MC is confident that our two Vietnamese suppliers are committed to strong sustainability standards and are working to apply them on the ground through ongoing training and structural improvements. We wish to reach out to our Group Companies to encourage similar standards. Working in partnership with our suppliers, we will continue to promote sustainable operations across the whole MC Group.

In December 2016, MC was provided an opportunity by Olam to visit Olam Colombia's*Olam Colombia is a subsidiary of Olam International Limited.* milling plant and coffee farms from which Olam Colombia sources its coffee in order to better understand Olam's philosophy and approach to sustainability. MC also toured another coffee plantation of the Colombian Coffee Growers Federation (FNC). In each of these locations, MC confirmed that there were no problems related to sustainable supply chain management such as forced labor or child labor. These visits also helped to identify areas for further improvement related to health and safety (e.g. additional safety signage), and these improvements were quickly implemented. In collaboration with MC Group companies, MC will continue to work with its suppliers to make these sorts of improvements throughout MC's supply chains.

In February 2016, representatives of MC's Corporate Sustainability Department (hereinafter “MC”) visited Mabroc Teas Pvt Ltd. (Mabroc), a tea producer based in Sri Lanka, to observe on-site operations and confirm whether or not MC was in full compliance with MC's Policy for Sustainable Supply Chain Management. A customer of MC wholly-owned subsidiary, MC Foods Ltd., Mabroc is itself a wholly-owned subsidiary of Hayleys PLC (Hayleys), one of Sri Lanka's largest multinational business conglomerates. In addition to teas and other agricultural products, Hayleys' diverse operations include textiles, power generation, tourism, and infrastructure projects. Mabroc specializes in the packing, exporting, and marketing of tea products, while the tea leaves that Mabroc uses in its products are sourced by another Hayleys subsidiary, Kelani Valley Plantations PLC (KVPL). MC also visited the KVPL plantations.

Both Mabroc and KVPL have received a number of environmental certifications, including those granted by the Rainforest Alliance*1Farms and forests that are certified by the Rainforest Alliance are managed according to rigorous environmental, social, and economic criteria designed to conserve wildlife; safeguard soils and waterways; protect workers, their families and local communities; and increase livelihoods.*1 and FSC*2FSC Certification ensures that timber, paper and pulp, and other forestry products come from responsibly managed forests that are evaluated to meet FSC's strict environmental and social standards.*2. They also participate in the UN's Global Compact, a voluntary initiative for enterprises to implement universal sustainability and socially responsible policies.

To confirm that both companies are in compliance with its aforementioned policy, MC began by holding hearings with management-level staff to better understand their environmentally and socially responsible philosophies. MC then visited the plantations, employee residences, educational and medical facilities, and the plants where the teas are being manufactured and packaged to verify that those philosophies are being adhered to. After interviewing employees, MC concluded its inspections by holding hearings with local residents to get a sense of both companies' community relations.

These inspections have convinced MC that Mabroc and KVPL not only are in full compliance with MC's policy, but are also carrying out their own investigations on Sri Lanka's forest eco-systems, providing their employees with housing and opportunities to educate their children, and ensuring that environmentally and socially responsible practices are a fundamental part of their business operations.

By continuing to visit its suppliers, MC shall confirm that no human-rights violations are taking place at any links in its supply chains, and at the same time, maintain sustainable supplies from environmentally and socially sound companies like Mabroc and KVPL.

In May 2014, MC representatives visited Ipanema Coffees, one of the world's largest coffee plantations, and coffee exporting company MC Coffee do Brasil Ltda., both of which are located in southeastern Brazil approximately 300km to the northwest of Sao Paolo. Ipanema Coffees is not only world-renowned for producing high-quality coffee beans but they also have a number of sustainability certifications including Rainforest Alliance, Fair Trade USA and UTZ Kapeh for having socially and environmentally responsible operations. On this visit, the MC representatives, together with members of the Rainforest Alliance, observed all stages of the operations right through to the after-harvest process. Through meetings with Ipanema Coffees' management, MC representatives confirmed that the plantation was working to provide safe, hygienic and healthy working conditions for employees, including temporary employees working during the harvesting period. With a full range of operations, from growing and harvesting to sorting and export, MC observed through this inspection that the plantation has an unwavering commitment to quality and an extremely high degree of awareness of the environmental and social dimensions of its operations.

At a plant of MC Coffee do Brasil Ltda., MC representatives inspected every stage of the after-harvest process, ranging from sorting to shipping of coffee beans. Inside the plant, guided by a policy of increasing labor efficiency, MC has been making efforts to automate its operations. The coffee beans are meticulously sorted based on size, density and color, with only the highest quality coffee beans selected for export. Similar to the Ipanema Coffees plantation, operations at the plant pay due consideration to the environment in addition to quality, being accredited with major certifications such as UTZ Kapeh and FLO-CERT, and MC has earned an excellent reputation around the world for its high-quality coffee.

MC has also worked closely with our suppliers in other countries and recommended that they work towards achieving Rainforest Alliance certification for their product. As a result, the Thang Loi Plantation in Vietnam achieved certification in 2011 and the Edelweiss Plantation in Tanzania did the same in 2015. In addition, MC Coffee do Brasil has supported small-scale farmers in achieving Fairtrade certification, and these close relationships have allowed MC to handle one of the largest volumes of Fairtrade certified product in Brazil. In this way, MC is further establishing a business model to source coffee beans that are not only of high quality, but also sustainably produced.

In February 2013, MC representatives visited a shrimp hatchery company and a shrimp processing company in southern Thailand, where they held interviews with management and inspected work sites.

At the hatchery company, the MC representatives inspected every stage of the process from the hatching of the eggs to the shipment of the juvenile shrimp 20 days after hatching. In the shrimp hatchery business, it is vital to properly control the temperature and humidity inside the hatchery as well as to ensure the safe use of chemicals from the perspective of occupational health and safety. The inspection confirmed that each facility has an air-conditioned break room equipped with water dispensers. It is also mandatory for workers to use masks and other protective equipment when handling chemicals. Moreover, each year these facilities have been awarded Best Aquaculture Practice (BAP) certification, which is issued by an international aquaculture standards certification organization. Our inspectors confirmed a very high level of environmental and social awareness.

At the shrimp processing company, MC representatives interviewed senior managers and personnel officers, as well as inspected the factory. This company meets the national labor standard in Thailand and also receives detailed audits from the government every year. The inspectors confirmed that MC has prepared a manual covering health and safety and harassment prevention from the standpoint of maintaining a proper workplace environment, and that MC runs a regular training program for employees. In addition, they confirmed that MC meets international standards regarding occupational health and safety and obtains third-party verifications.